In the complex landscape of industrial equipment, if controllers are the brains, then three-phase asynchronous motors are undoubtedly the "heart" of the industry. Despite the constant evolution of drive technology, three-phase asynchronous motors remain the dominant force in the global industrial power drive market due to their inherent advantages of simple structure, reliable operation, and low maintenance costs. From large ventilation systems in Europe to mining conveyor belts in South America, this classic power source quietly supports the continuous operation of global manufacturing.

As a professional supplier of transmission equipment, TATA Drive understands that for international buyers, purchasing motors is not just about price but also about energy efficiency, adaptability to working conditions, and compatibility with global standards. We are committed to providing high-quality motors that meet International Electrotechnical Commission (IEC) standards, injecting continuous power into your equipment.

With the increasing global restrictions on carbon emissions and energy consumption, the European Union (IE3/IE4 standards), the United States (NEMA Premium), and major Asian economies have all set higher entry requirements for motor energy efficiency. Although a low-efficiency motor has a low purchase cost, the electricity costs it consumes over the years can often be several times its value.

TATA Drive's series of three-phase asynchronous motors closely follow the steps of international energy efficiency reforms. We have optimized the slot design of the stator and rotor and used high-purity copper winding and low-loss silicon steel sheets, significantly reducing iron loss and copper loss. This means our motors have less loss and lower heat generation when converting electrical energy into mechanical energy. For end factories, using TATA Drive's high-efficiency motors not only meets local environmental regulations but also significantly reduces long-term electricity operating costs, achieving a win-win situation for economic benefits and social responsibility.

The environments of industrial sites vary widely, from dusty cement plants to highly humid food processing workshops, requiring motors with strong "immunity." The reason why three-phase asynchronous motors are called the "main horse power" of the industry is due to their sturdy and durable nature.

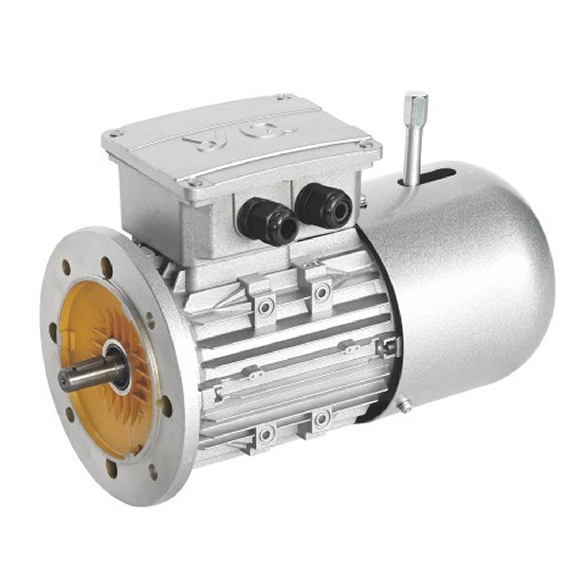

In TATA Drive's manufacturing process, we particularly emphasize the protection and insulation performance of the motors. Our products come standard with a high protection level (such as IP55), effectively blocking the intrusion of dust and water splashes. In the insulation system, we use F-class or H-class insulation materials, and undergo vacuum pressure impregnation (VPI) treatment to ensure that the motors can maintain stable electrical performance in harsh conditions such as high temperatures, overload, or frequent starts, avoiding unplanned downtime caused by short circuits or burnout. Whether driving pumps, fans, compressors, or gearboxes, our motors deliver long-lasting stable output.

One significant challenge in international trade is the inconsistency of power grid standards worldwide. From 400V/50Hz in Europe to 460V/60Hz in North America, and special voltage requirements in some Asian countries, equipment manufacturers often need to match different motors for different markets.

TATA Drive provides a truly global power solution. Our three-phase asynchronous motors feature wide voltage and wide frequency designs, capable of flexibly adapting to the power grid environments of multiple countries and regions. Additionally, we offer modular customization services, whether it's special flange mounting dimensions, shaft extension lengths, or anti-corrosion coatings tailored to specific climates, we can respond quickly. Coupled with our extensive reducer product line, TATA Drive can provide you with an integrated "motor + reducer" transmission combination, simplifying your supply chain management, and enabling your equipment to sell seamlessly worldwide.

Although three-phase asynchronous motors are traditional products, with the support of new materials and processes, they have been revitalized. TATA Drive promises to guard every rotation of your equipment with high-efficiency, durable products that meet global standards.