Clients send requirements and share technical parameters (torque, speed), our engineers confirm compatibility with export specs via data sheets.

Clients send requirements and share technical parameters (torque, speed), our engineers confirm compatibility with export specs via data sheets.

R&D team designs with material strength calculations, gear ratio optimization for client's industrial machinery.

Finite element analysis tests structural durability under extreme loads, technical feasibility report generated.

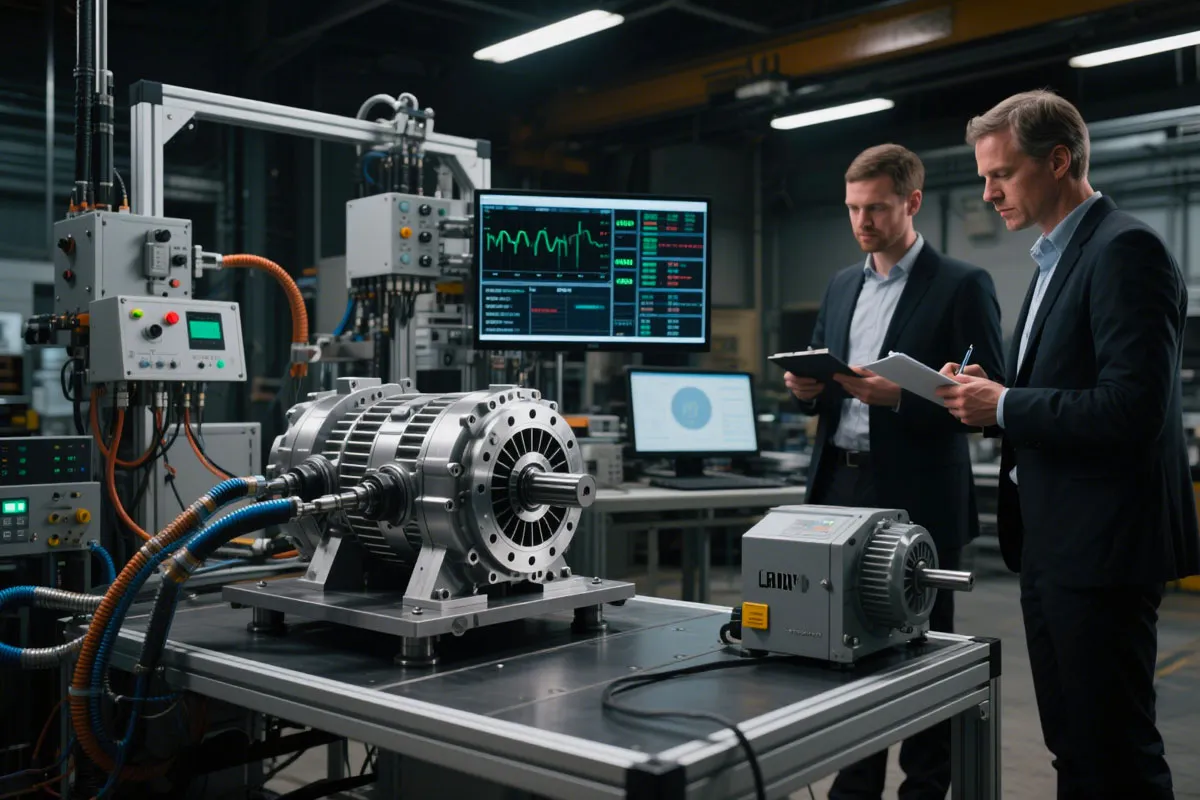

Prototype undergoes torque testing, noise level measurement to match client's machinery integration needs.

Check adherence to client's machinery standards, adjust interface dimensions for seamless integration.

After confirming the written materials, sign the sales contract and start mass production after receiving the advance payment.

Random samples tested for backlash, efficiency, data logged to meet client's technical acceptance criteria.

Client completes the acceptance, pays the final payment, and delivers the cargo.

Main materials: high-strength cast iron housing, 42CrMo alloy steel gears.

Production tech: precision gear hobbing, CNC machining, heat treatment.

Features: IP65 protection, low noise (<65dB), high torque (up to 2000N·m), corrosion resistance, ideal for humid food processing environments.

OEM Service

Factory prices

TATA Drive offers Custom Solutions. Our expert team crafts tailored designs, optimizing performance and cost. Unleash your vehicle's potential with our bespoke services.

Our custom solutions boost functionality. By optimizing components for your specific use cases—whether speed, durability, or energy efficiency—we deliver drives that outperform standard models, driving productivity and reliability.

Customization from GTR DRIVE avoids unnecessary features. You pay only for what you need, reducing long-term operational costs while ensuring the drive meets your exact performance requirements, maximizing value.

Post-export, our global service centers provide prompt support—technical troubleshooting, parts replacement, and upgrades. This ensures your customized drives maintain efficiency, no matter their location across the globe.

GTR DRIVE's export customizations never sacrifice quality. Each unit undergoes rigorous testing—vibration, temperature, and load checks—meeting global benchmarks. This ensures reliability in diverse environments, building trust in every market.