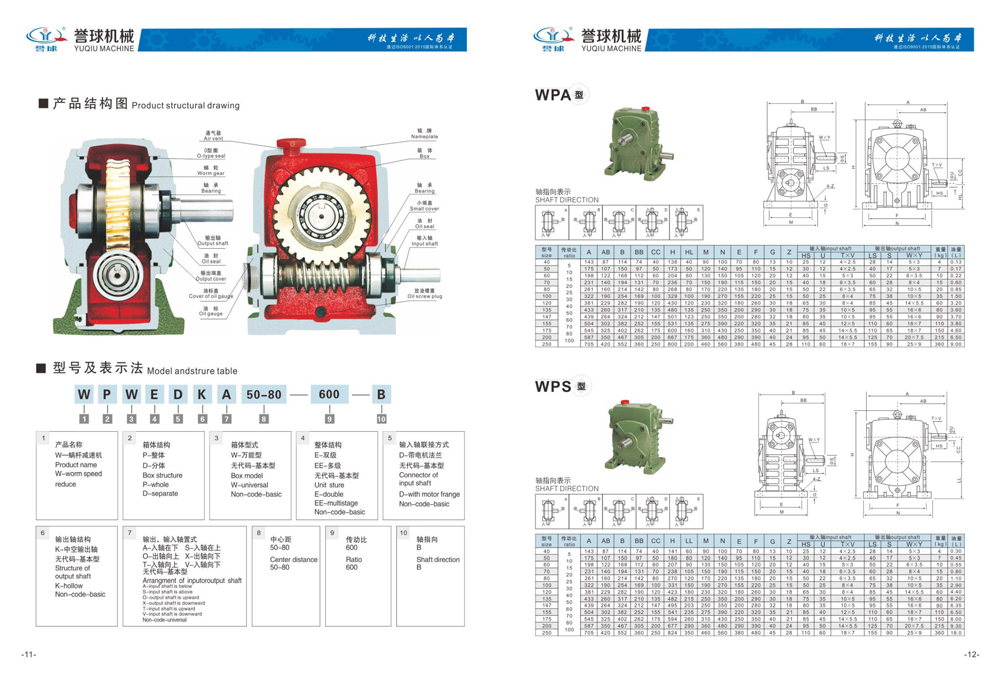

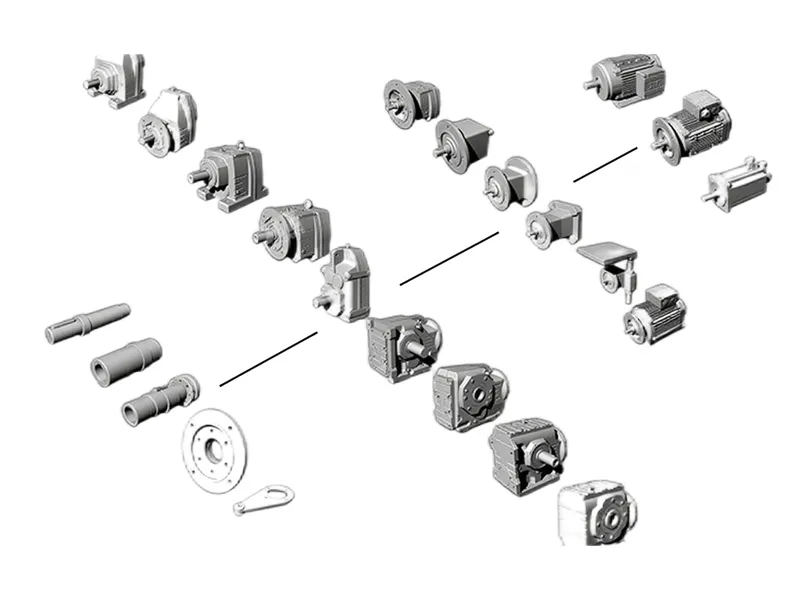

The full range of products includes motors, input interfaces, output modules, installation forms, etc., which can be personalized designed and manufactured according to customer needs.

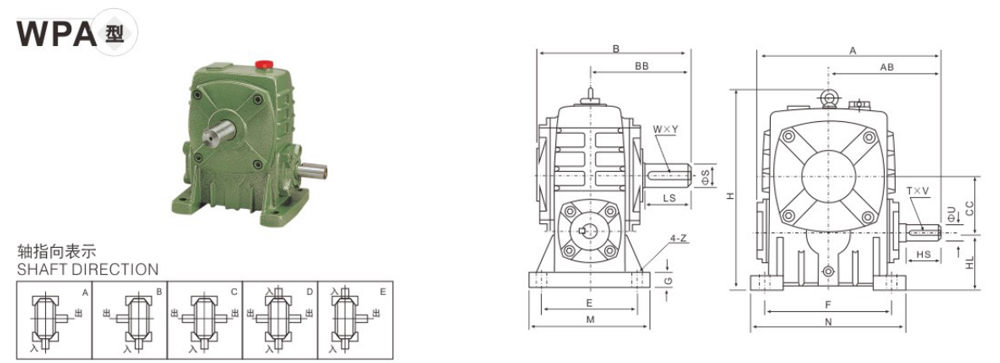

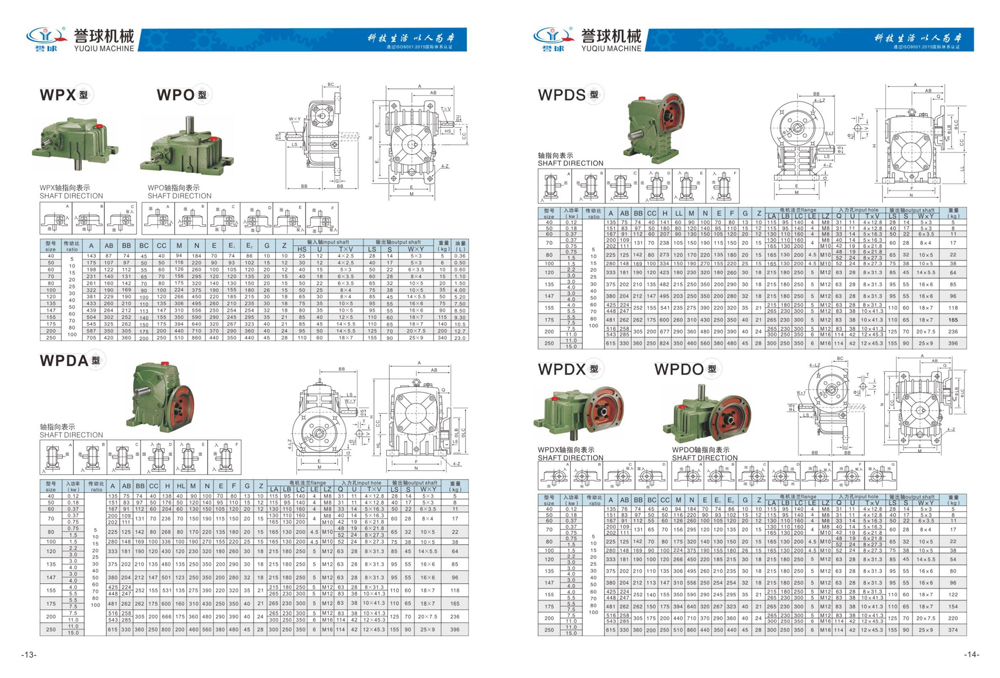

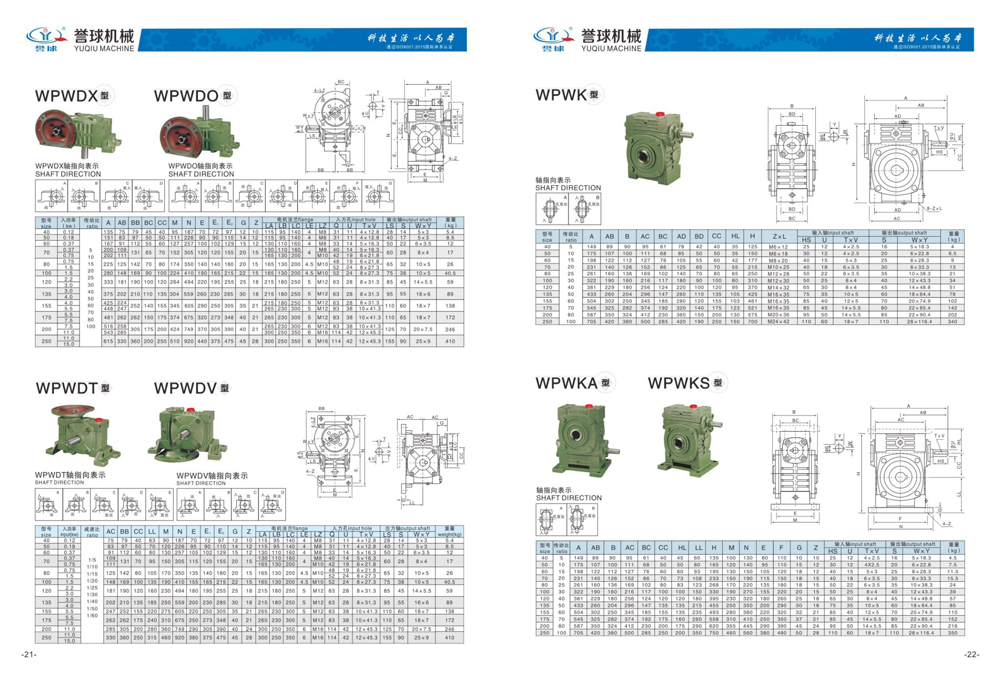

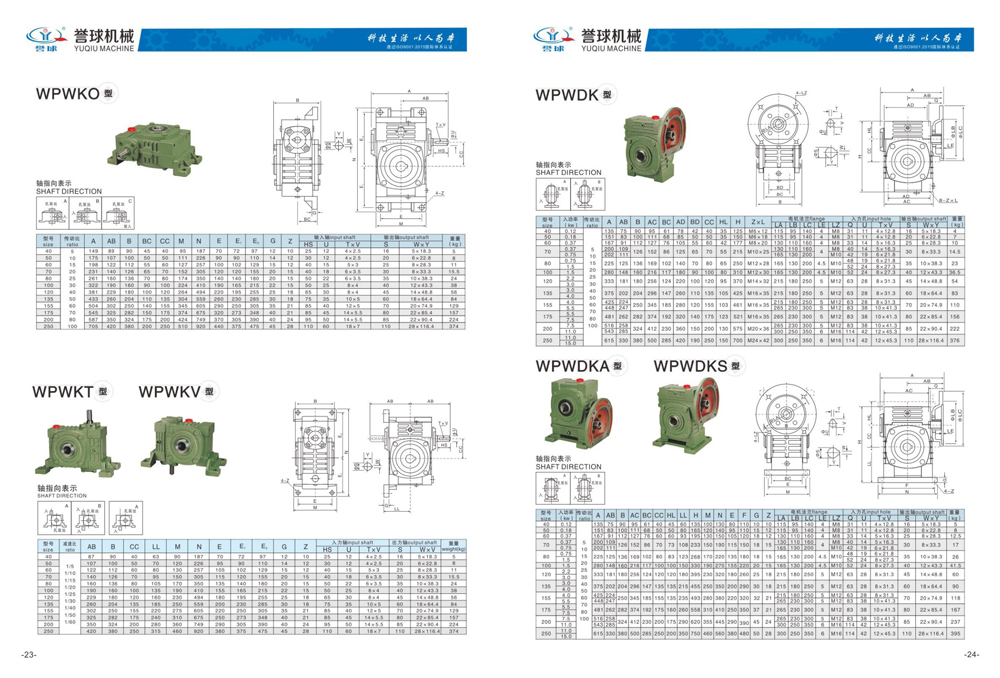

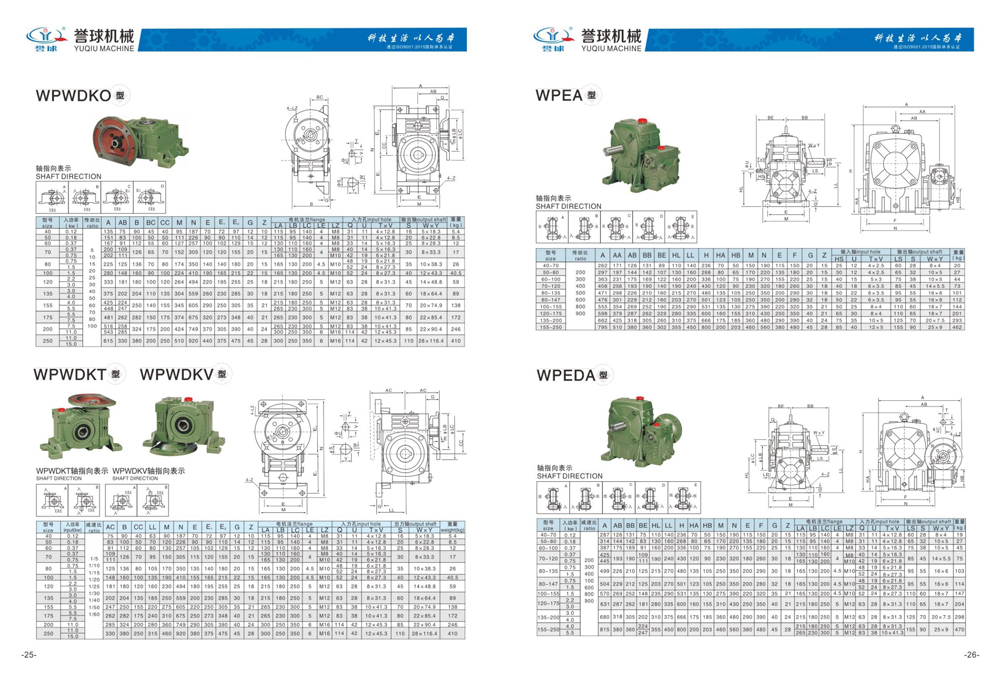

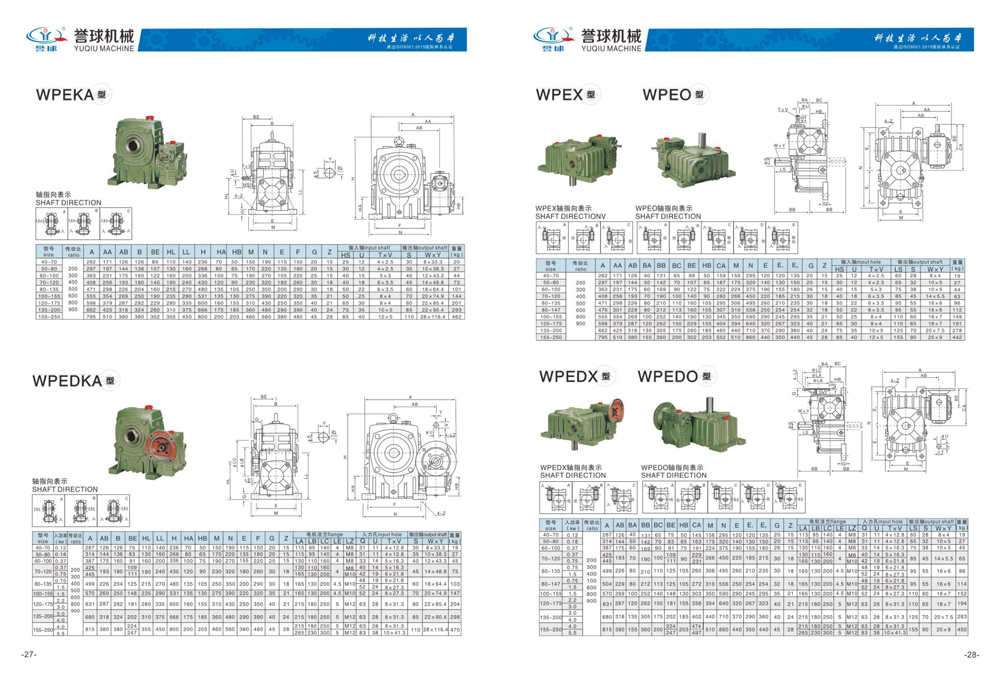

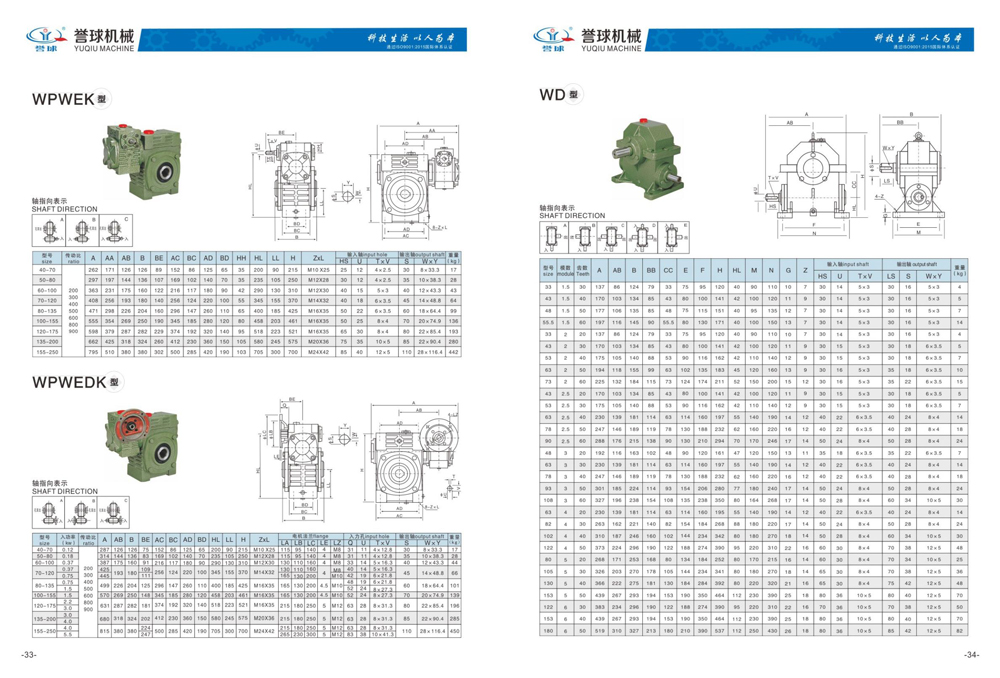

| size | ratio | A | AB | B | BB | CC | H | HL | M | N | E | F | G | Z | input shaft | output shaft | (kg) | (L) | ||||

| HS | U | T×V | LS | S | W×Y | |||||||||||||||||

| 40 | 5 10 15 | 143 | 87 | 114 | 74 | 40 | 138 | 40 | 90 | 100 | 70 | 80 | 13 | 10 | 25 | 12 | 4×2.5 | 28 | 14 | 5×3 | 4二 | 0.13 |

| 50 | 175 | 107 | 150 | 97 | 50 | 173 | 50 | 120 | 140 | 95 | 110 | 15 | 12 | 30 | 12 | 4×2.5 | 40 | 17 | 5×3 | 7 | 0.17 | |

| 60 | 198 | 122 | 168 | 112 | 60 | 204 | 60 | 130 | 150 | 105 | 120 | 20 | 12 | 40 | 15 | 5×3 | 50 | 22 | 6×3.5 | 10 | 0.22 | |

| 70 | 231 | 140 | 194 | 131 | 70 | 236 | 70 | 150 | 190 | 115 | 150 | 20 | 15 | 40 | 18 | 6×3.5 | 60 | 28 | 8×4 | 15 | 0.60 | |

| 80 | 20 25 30 40 | 261 | 160 | 214 | 142 | 80 | 268 | 80 | 170 | 220 | 135 | 180 | 20 | 15 | 50 | 22 | 6×3.5 | 65 | 32 | 10×5 | 20 | 0.85 |

| 100 | 322 | 190 | 254 | 169 | 100 | 329 | 100 | 190 | 270 | 155 | 220 | 25 | 15 | 50 | 25 | 8×4 | 75 | 38 | 10×5 | 35 | 1.50 | |

| 120 | 381 | 229 | 282 | 190 | 120 | 430 | 120 | 230 | 320 | 180 | 260 | 30 | 18 | 65 | 30 | 8×4 | 85 | 45 | 14×5.5 | 60 | 3.20 | |

| 135 | 433 | 260 | 317 | 210 | 135 | 480 | 135 | 250 | 350 | 200 | 290 | 30 | 18 | 75 | 35 | 10×5 | 95 | 55 | 16×6 | 80 | 3.60 | |

| 147 | 50 60 70 | 439 | 264 | 324 | 212 | 147 | 501 | 123 | 250 | 350 | 200 | 280 | 32 | 18 | 80 | 35 | 10×5 | 95 | 55 | 16×6 | 90 | 3.70 |

| 155 | 504 | 302 | 382 | 252 | 155 | 531 | 135 | 275 | 390 | 220 | 320 | 35 | 21 | 85 | 40 | 12×5 | 110 | 60 | 18×7 | 110 | 3.80 | |

| 175 | 545 | 325 | 402 | 262 | 175 | 600 | 160 | 310 | 430 | 250 | 350 | 40 | 21 | 85 | 45 | 14×5.5 | 110 | 65 | 18×7 | 150 | 4.60 | |

| 200 | 80 | 587 | 350 | 467 | 305 | 200 | 667 | 175 | 360 | 480 | 290 | 390 | 40 | 24 | 95 | 50 | 14×5.5 | 125 | 70 | 20×7.5 | 215 | 6.50 |

| 250 | 100 | 705 | 420 | 552 | 360 | 250 | 800 | 200 | 460 | 560 | 380 | 480 | 45 | 28 | 110 | 60 | 18×7 | 155 | 90 | 25×9 | 360 | 9.00 |

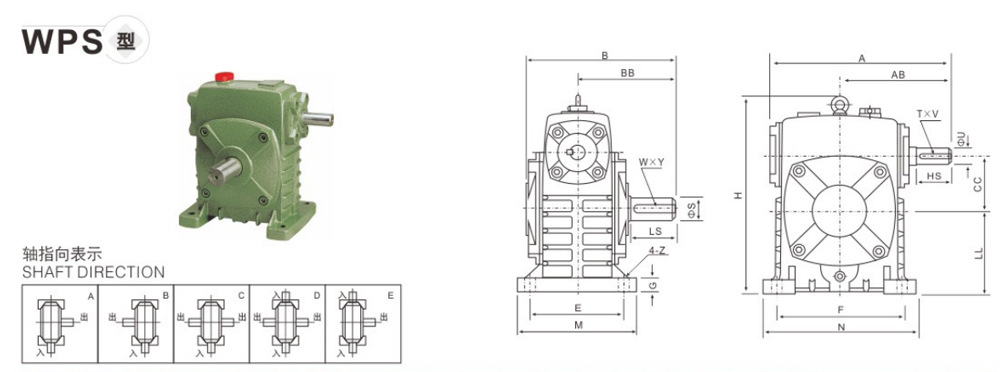

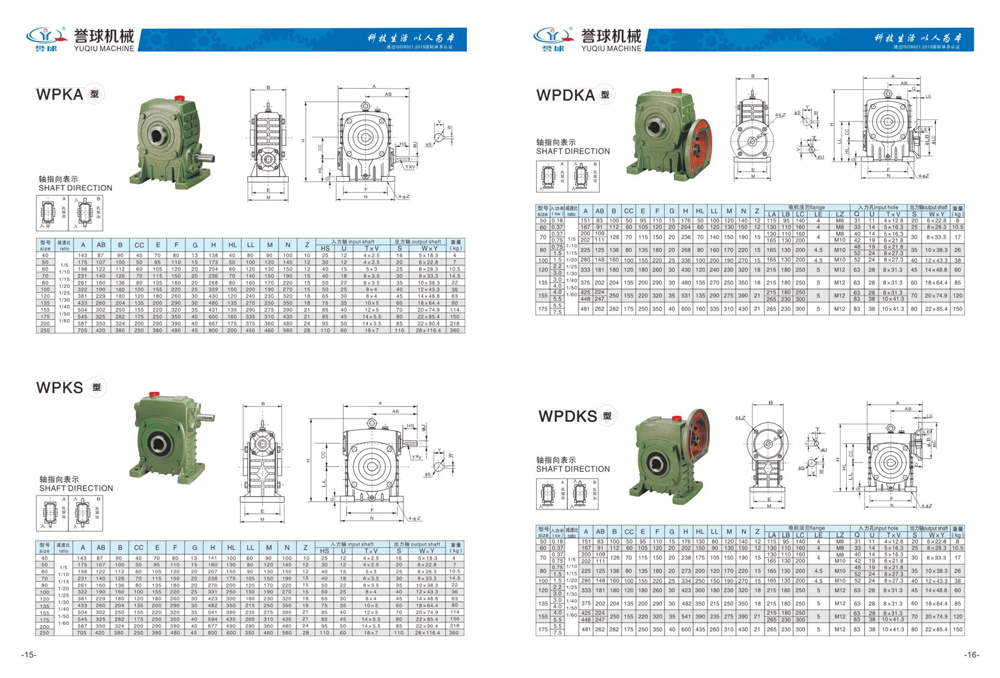

| size | ratio | A | AB | B | BB | cC | H | LL | M | N | E | F | G | Z | input shaft | output shaft | (kg) | (L) | ||||

| HS | U | T×V | LS | S | W×Y | |||||||||||||||||

| 40 | 5 10 15 20 25 30 40 50 | 143 | 87 | 114 | 74 | 40 | 141 | 60 | 90 | 100 | 70 | 80 | 13 | 10 | 25 | 12 | 4×2.5 | 28 | 14 | 5×3 | 4 | 0.30 |

| 50 | 175 | 107 | 150 | 97 | 50 | 180 | 80 | 120 | 140 | 95 | 110 | 15 | 12 | 30 | 12 | 4×2.5 | 40 | 17 | 5×3 | 7 | 0.45 | |

| 60 | 198 | 122 | 168 | 112 | 60 | 207 | 90 | 130 | 150 | 105 | 120 | 20 | 12 | 40 | 15 | 5×3 | 50 | 22 | 6×3.5 | 10 | 0.55 | |

| 70 | 231 | 140 | 194 | 131 | 70 | 238 | 105 | 150 | 190 | 115 | 150 | 20 | 15 | 40 | 18 | 6×3.5 | 60 | 28 | 8×4 | 15 | 0.80 | |

| 80 | 261 | 160 | 214 | 142 | 80 | 270 | 120 | 170 | 220 | 135 | 180 | 20 | 15 | 50 | 22 | 6×3.5 | 65 | 32 | 10×5 | 20 | 1.10 | |

| 100 | 322 | 190 | 254 | 169 | 100 | 331 | 150 | 190 | 270 | 155 | 220 | 25 | 15 | 50 | 25 | 8×4 | 75 | 38 | 10×5 | 35 | 2.90 | |

| 120 | 381 | 229 | 282 | 190 | 120 | 423 | 180 | 230 | 320 | 180 | 260 | 30 | 18 | 65 | 30 | 8×4 | 85 | 45 | 14×5.5 | 60 | 4.40 | |

| 135 | 433 | 260 | 317 | 210 | 135 | 482 | 215 | 250 | 350 | 200 | 290 | 30 | 18 | 75 | 35 | 10×5 | 95 | 55 | 16×6 | 80 | 6.20 | |

| 147 | 439 | 264 | 324 | 212 | 147 | 495 | 203 | 250 | 350 | 200 | 280 | 32 | 18 | 80 | 35 | 10×5 | 95 | 55 | 16×6 | 90 | 6.35 | |

| 155 | 60 70 80 | 504 | 302 | 382 | 252 | 155 | 541 | 235 | 275 | 390 | 220 | 320 | 35 | 21 | 85 | 40 | 12×5 | 110 | 60 | 18×7 | 110 | 6.50 |

| 175 | 545 | 325 | 402 | 262 | 175 | 594 | 260 | 310 | 430 | 250 | 350 | 40 | 21 | 85 | 45 | 14×5.5 | 110 | 65 | 18×7 | 150 | 8.00 | |

| 200 | 587 | 350 | 467 | 305 | 200 | 677 | 290 | 360 | 480 | 290 | 390 | 40 | 24 | 95 | 50 | 14×5.5 | 125 | 70 | 20×7.5 | 215 | 9.30 | |

| 250 | 100 | 705 | 420 | 552 | 360 | 250 | 824 | 350 | 460 | 560 | 380 | 480 | 45 | 28 | 110 | 60 | 18×7 | 155 | 90 | 25×9 | 360 | 18.0 |

Housing Material:

Aluminum alloy (small sizes) or cast iron (large models) balances lightweight design with ruggedness, ensuring corrosion resistance and efficient heat dissipation.

Transmission Capacity:

Wide ratio range (7–10000) and high torque output (13–7100N·m) handle heavy loads, delivering stable power transfer in industrial machinery.

Noise Control:

Precision-machined components and optimized meshing reduce noise to <50dB, suitable for noise-sensitive environments like food processing.

Mounting Options:

Compatible with foot, flange, or shaft mounting; integrates seamlessly with IEC motors for flexible installation in diverse setups.

Special Versions:

EP series features FDA-approved coating and food-grade lubricant, ideal for hygienic or corrosive environments (food, chemical, maritime).

The full range of products includes motors, input interfaces, output modules, installation forms, etc., which can be personalized designed and manufactured according to customer needs.

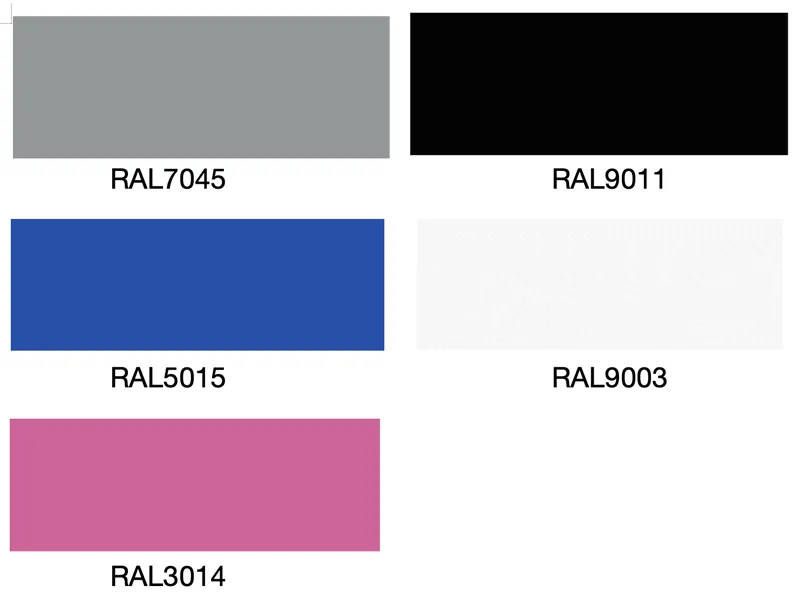

We offer multiple color schemes such as RAL7045 (gray), RAL9011 (black), RAL5015 (blue), RAL9003 (white), RAL3014 (purple), etc. Customers can choose the corresponding product color according to their different needs.

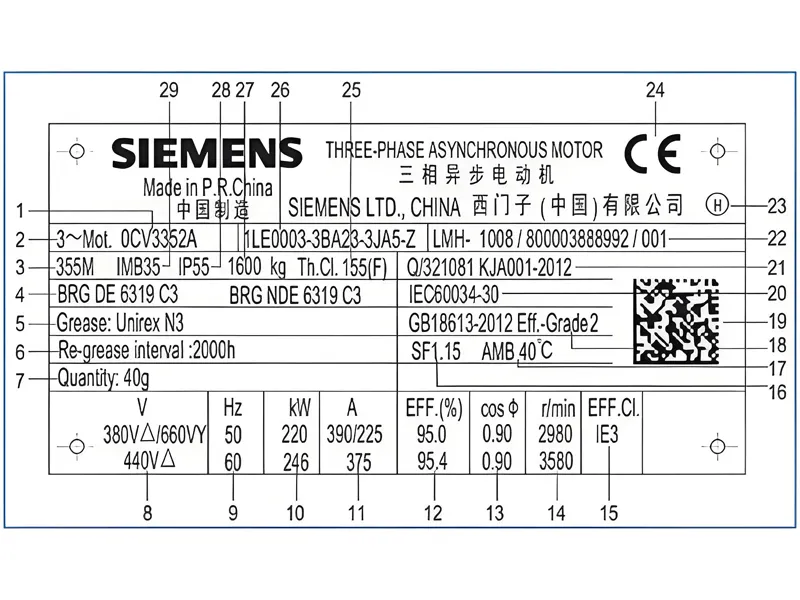

Our nameplate is made of stainless steel laser printing technology, which can be customized according to the different needs of customers, especially by adding a product QR code. Scanning the QR code can quickly access product information and sales service information.

Conventional packaging forms include cardboard boxes, pallets, and wooden boxes. We can also customize the outer box packaging according to customer needs.