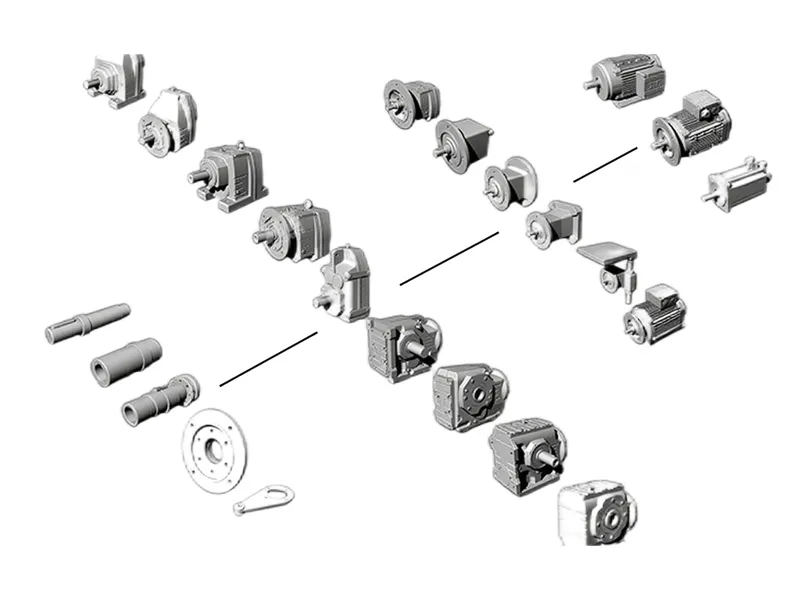

The full range of products includes motors, input interfaces, output modules, installation forms, etc., which can be personalized designed and manufactured according to customer needs.

| XG30 180 Nm | |||||||||||||||||

| i | n1=1400 min⁻¹ | n1=900 min⁻¹ | n1 =500 min-¹ | |||||||||||||

| n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rni N | n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rn1 N | n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rn1 N | ||||||

| XG30 | 30 | 7.0 | 200 | 137 | 2.9 | 350 | 128 | 150 | 2.0 | 400 | 71 | 180 | 1.3 | 500 | |||

| 10 | 140 | 137 | 2.1 | 350 | 90 | 150 | 1.4 | 400 | 50 | 180 | 1.0 | 500 | |||||

| 12.5 | 112 | 137 | 1.6 | 350 | 72 | 150 | 1.1 | 400 | 40 | 180 | 0.8 | 500 | |||||

| XG35 420Nm | |||||||||||||||||

| i | n1=1400 min⁻¹ | n1=900 min⁻¹ | n1 =500 min-¹ | |||||||||||||

| n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rn1 N | n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rn1 N | n2 min-1 | Mn2 Nm | Pn1 kW | Rn1 N | ||||||

| XG35 | 35 | 5 | 280 | 200 | 6.0 | 700 | 180 | 250 | 4.8 | 800 | 100 | 350 | 3.8 | 1000 | |||

| XG35 | 35 | D | 10 | 140 | 300 | 4.6 | 500 | 90 | 350 | 3.5 | 600 | 50 | 400 | 2.2 | 750 | ||

| 15 | 93 | 350 | 3.6 | 500 | 60 | 400 | 2.6 | 600 | 33 | 400 | 1.5 | 750 | |||||

| 20 | 70 | 380 | 3.0 | 500 | 45 | 400 | 2.0 | 600 | 25 | 400 | 1.1 | 750 | |||||

| 25 | 56 | 400 | 2.5 | 500 | 36 | 400 | 1.6 | 600 | 20 | 420 | 0.9 | 750 | |||||

| XG40 950Nm | |||||||||||||||||

| i | n1=1400 min⁻¹ | n1=900 min⁻¹ | n1 =500 min-1 | |||||||||||||

| n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rn1 N | n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rn1 N | n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rn1 N | ||||||

| XG40 | 40 | 5 | 280 | 480 | 14.4 | 1000 | 180 | 550 | 10.6 | 1200 | 100 | 700 | 7.5 | 1500 | |||

| 45 | 10 | 140 | 600 | 9.2 | 850 | 90 | 750 | 7.4 | 950 | 50 | 800 | 4.4 | 1200 | ||||

| XG40 | 40 45 | D | 12.5 | 112 | 700 | 8.1 | 850 | 72 | 780 | 5.8 | 950 | 40 | 820 | 3.4 | 1200 | ||

| 15 | 93 | 750 | 7.7 | 850 | 60 | 800 | 5.3 | 950 | 33 | 850 | 3.1 | 1200 | |||||

| 20 | 70 | 780 | 6.1 | 850 | 45 | 800 | 4.0 | 950 | 25 | 850 | 2.4 | 1200 | |||||

| 25 | 56 | 800 | 4.9 | 850 | 36 | 850 | 3.4 | 950 | 20.0 | 900 | 2.0 | 1200 | |||||

| 30.5 | 46 | 800 | 3.9 | 850 | 29.5 | 900 | 2.8 | 950 | 16.4 | 950 | 1.7 | 1200 | |||||

| XG45 1400Nm | |||||||||||||||||

| i | n1=1400 min⁻¹ | n1=900 min⁻¹ | n1 =500 min-1 | |||||||||||||

| n2 min-1 | Mn2 Nm | Pn1 kW | Rn1 N | n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rni N | n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rn1 N | ||||||

| XG45 | 45 50 55 | 5 | 280 | 850 | 26 | 1500 | 180 | 950 | 18.4 | 1700 | 100 | 1100 | 11.8 | 2150 | |||

| XG45 | 45 50 55 | D | 10 | 140 | 1000 | 15.4 | 1150 | 90 | 1200 | 11.9 | 1300 | 50 | 1300 | 7.2 | 1650 | ||

| 12.5 | 112 | 1100 | 13.9 | 1150 | 72 | 1200 | 9.7 | 1300 | 40 | 1300 | 5.9 | 1650 | |||||

| 15 | 93 | 1200 | 12.3 | 1150 | 60 | 1250 | 8.3 | 1300 | 33 | 1300 | 4.8 | 1650 | |||||

| 20 | 70 | 1250 | 9.8 | 1150 | 45 | 1300 | 6.5 | 1300 | 25 | 1350 | 3.8 | 1650 | |||||

| 25 | 56 | 1300 | 8.0 | 1150 | 36 | 1350 | 5.4 | 1300 | 20.0 | 1400 | 3.1 | 1650 | |||||

| 30.5 | 46 | 1300 | 6.6 | 1150 | 29.5 | 1350 | 4.4 | 1300 | 16.4 | 1400 | 2.5 | 1650 | |||||

| XG50 2300Nm | |||||||||||||||||

| i | n1=1400 min⁻¹ | n1=900 min⁻¹ | n1 =500 min-1 | |||||||||||||

| n2 min-1 | Mn2 Nm | Pn1 kW | Rn1 N | n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rni N | n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rn1 N | ||||||

| XG50 | 50 55 60 | 5 | 280 | 1400 | 42 | 2250 | 180 | 1700 | 33.0 | 2500 | 100 | 1900 | 20.0 | 3100 | |||

| XG50 | 50 55 60 | D | 10 | 140 | 1750 | 27.0 | 1700 | 90 | 1900 | 18.8 | 1900 | 50 | 2000 | 11.0 | 2400 | ||

| 12.5 | 112 | 1800 | 21 | 1700 | 72 | 1900 | 14.5 | 1900 | 40 | 2000 | 8.4 | 2400 | |||||

| 15 | 93 | 1900 | 19.5 | 1700 | 60 | 1950 | 12.9 | 1900 | 33 | 2100 | 7.7 | 2400 | |||||

| 20 | 70 | 1950 | 14.8 | 1700 | 45 | 2000 | 9.8 | 1900 | 25 | 2100 | 5.7 | 2400 | |||||

| 25 | 56 | 2000 | 12.3 | 1700 | 36 | 2100 | 8.3 | 1900 | 20.0 | 2300 | 5.1 | 2400 | |||||

| 30 | 47 | 2000 | 10.3 | 1700 | 30.0 | 2100 | 6.9 | 1900 | 16.7 | 2300 | 4.2 | 2400 | |||||

| XG60 3600Nm | |||||||||||||||||

| i | n1=1400 min⁻¹ | n1=900 min⁻¹ | n1 =500 min-1 | |||||||||||||

| n2 min-1 | Mn2 Nm | Pn1 kW | Rn1 N | n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rni N | n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rn1 N | ||||||

| XG60 | 60 70 | 5 | 280 | 1900 | 57 | 3200 | 180 | 2100 | 41.0 | 3600 | 100 | 2900 | 32.0 | 4500 | |||

| XG60 | 60 70 | D | 10 | 140 | 3100 | 48.0 | 2600 | 90 | 3200 | 32.0 | 2900 | 50 | 3300 | 18.2 | 3600 | ||

| 12.5 | 112 | 3100 | 37 | 2600 | 72 | 3200 | 24.0 | 2900 | 40 | 3300 | 14.0 | 3600 | |||||

| 15 | 93 | 3200 | 33 | 2600 | 60 | 3300 | 22.0 | 2900 | 33 | 3550 | 13.0 | 3600 | |||||

| 20 | 70 | 3250 | 25 | 2600 | 45 | 3400 | 16.6 | 2900 | 25 | 3550 | 9.6 | 3600 | |||||

| 25 | 56 | 3300 | 20.0 | 2600 | 36 | 3500 | 13.9 | 2900 | 20.0 | 3600 | 7.9 | 3600 | |||||

| 30.5 | 46 | 3300 | 16.7 | 2600 | 29.5 | 3500 | 11.4 | 2900 | 16.4 | 3600 | 6.5 | 3600 | |||||

| XG70 5100Nm | |||||||||||||||||

| i | n1=1400 min⁻¹ | n1=900 min⁻¹ | n1 =500 min-1 | |||||||||||||

| n2 min-1 | Mn2 Nm | Pn1 kW | Rn1 N | n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rni N | n2 min⁻¹ | Mn2 Nm | Pn1 kW | Rn1 N | ||||||

| XG70 | 70 85 | 5 | 280 | 2600 | 78 | 3700 | 180 | 3000 | 58.0 | 4200 | 100 | 4000 | 43.0 | 5200 | |||

| XG70 | 70 85 | D | 10 | 140 | 3800 | 59.0 | 3400 | 90 | 4400 | 44.0 | 3800 | 50 | 4500 | 25.0 | 4750 | ||

| 12.5 | 112 | 4000 | 51 | 3400 | 72 | 4400 | 36.0 | 3800 | 40 | 4500 | 20.0 | 4750 | |||||

| 15 | 93 | 4400 | 45 | 3400 | 60 | 4500 | 30.0 | 3800 | 33 | 4900 | 18.0 | 4750 | |||||

| 20 | 70 | 4500 | 34 | 3400 | 45 | 4600 | 22.0 | 3800 | 25 | 5000 | 13.6 | 4750 | |||||

| 25 | 56 | 4600 | 28.0 | 3400 | 36 | 4900 | 19.4 | 3800 | 20.0 | 5100 | 11.2 | 4750 | |||||

| 30.5 | 46 | 4600 | 23.0 | 3400 | 29.5 | 4900 | 16.0 | 3800 | 16.4 | 5100 | 9.2 | 4750 | |||||

Wide Torque & Power Coverage:

Torque ranges 180 - 17000N·m, power 0.8 - 226kW. Models XG30 - XG125 meet both light food machinery and heavy mining equipment needs.

Efficient Helical Gear Transmission:

Adopts helical gearing with carburized low-carbon alloy steel. Ensures smooth meshing, matching 500 - 1400rpm input speed for low power loss.

High Customization Flexibility:

Supports OEM/ODM, like shaft size and color. Fluor elastomer seals or backstops can be added to fit special working conditions.

Suitable for Multiple Heavy-Duty Scenarios:

Ideal for belt conveyors, concrete mixers and mines. Its robust structure copes with continuous load in construction and energy industries.

Reliable & Durable Structure:

Equipped with lifting lugs and high-quality seals. Hardened gears and sturdy housing offer 1-3 years warranty, ensuring long-term stable operation.

The full range of products includes motors, input interfaces, output modules, installation forms, etc., which can be personalized designed and manufactured according to customer needs.

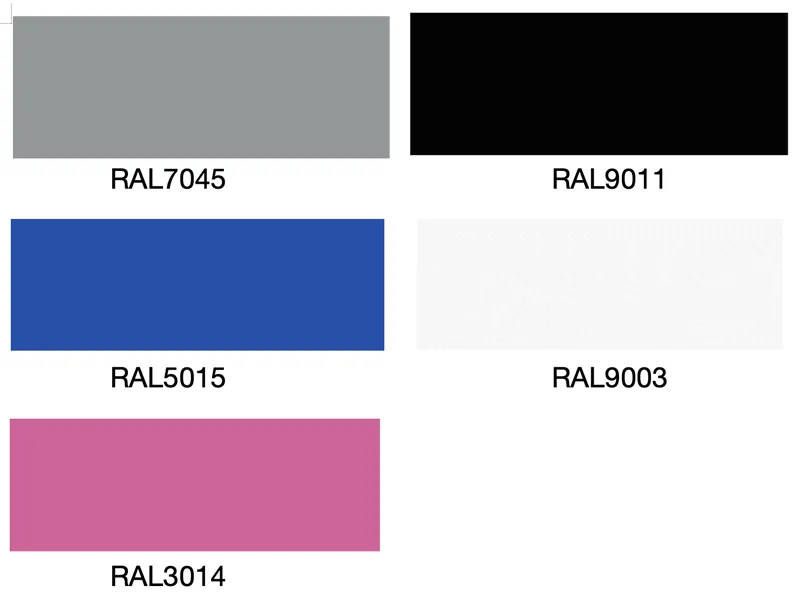

We offer multiple color schemes such as RAL7045 (gray), RAL9011 (black), RAL5015 (blue), RAL9003 (white), RAL3014 (purple), etc. Customers can choose the corresponding product color according to their different needs.

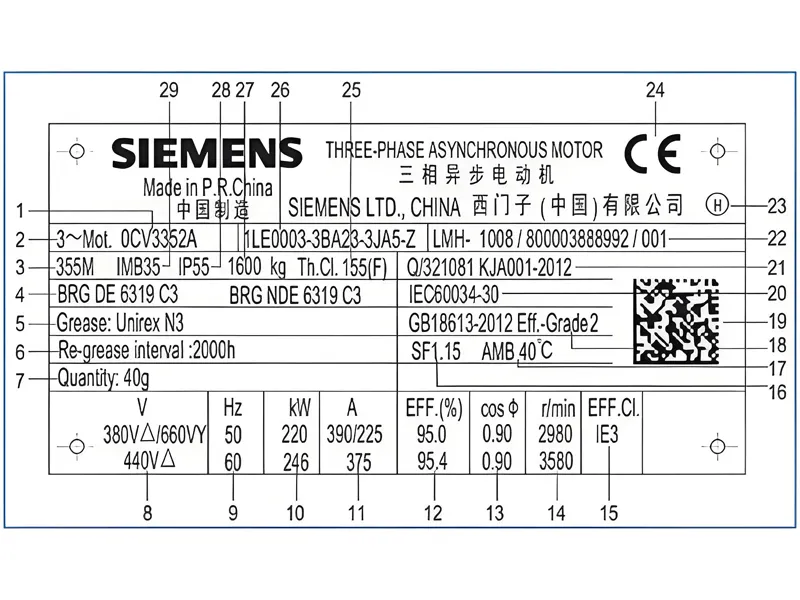

Our nameplate is made of stainless steel laser printing technology, which can be customized according to the different needs of customers, especially by adding a product QR code. Scanning the QR code can quickly access product information and sales service information.

Conventional packaging forms include cardboard boxes, pallets, and wooden boxes. We can also customize the outer box packaging according to customer needs.